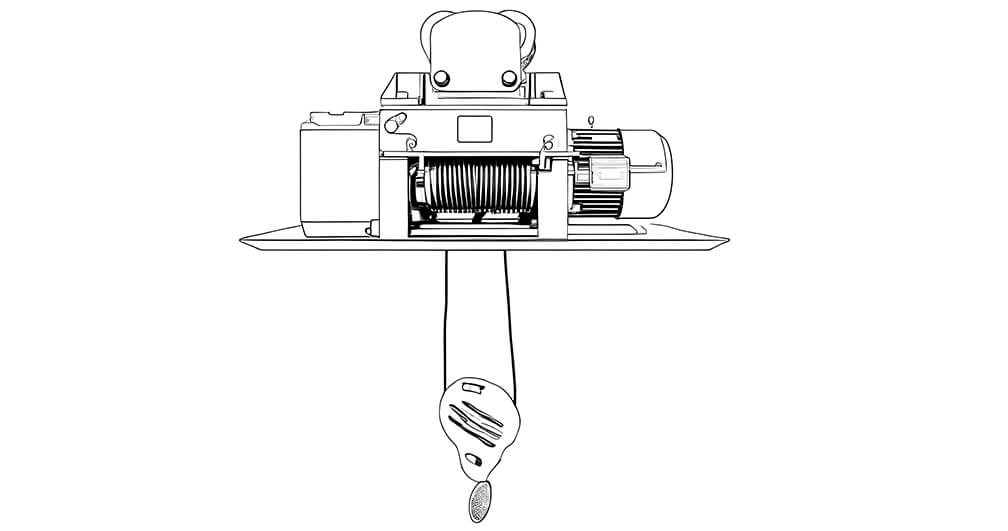

The metallurgical electric hoist is a heavy-duty lifting equipment specifically designed for the metallurgical industry, widely used in steel plants, electric furnace workshops, casting workshops, and other high-temperature, heavy-load environments. The equipment combines advanced electrical control technology and mechanical structure design, offering efficiency, safety, and durability. The design of the metallurgical electric hoist incorporates multiple protection features, dual lifting brakes, and advanced control technologies, ensuring stable operation under high loads and intense working conditions. Additionally, the metallurgical electric hoist can be paired with various bridge and gantry cranes, offering flexible lifting solutions. Whether for steelmaking, metal processing, or heavy equipment lifting, the metallurgical electric hoist guarantees efficient and safe completion of various lifting tasks, making it an essential piece of equipment in the metallurgical industry.

The metallurgical electric hoist is a high-efficiency lifting equipment specifically designed for the metallurgical industry. It is widely used in steel plants, metallurgical workshops, electric furnace workshops, foundry workshops, and other environments. It can handle heavy lifting tasks and is suitable for high-temperature and heavy-load working conditions. The metallurgical electric hoist can be paired with bridge cranes, gantry cranes, and other equipment for use in steelmaking, metal processing, casting, and other industries.

The metallurgical electric hoist adopts advanced multi-level safety protection technologies, including overload protection, limit switches, and emergency brake systems, ensuring stable operation in high-intensity environments and ensuring the safety of personnel and materials.

Made from high-strength alloy materials, the metallurgical electric hoist has excellent high-temperature resistance and corrosion resistance, making it capable of handling lifting tasks in high-temperature and harsh conditions of metallurgical workshops.

The hoist uses a high-efficiency electric hoist system, offering fast and precise lifting and lowering, which enhances operational efficiency and reduces downtime.

In addition to basic safety features, the metallurgical electric hoist also includes special functions like high-temperature resistance and explosion-proof capabilities to meet the specific working demands of the metallurgical industry.

| Model Specification | HY1T | HY2T | HY3T | HY5T | HY10T | ||

| Lifting height | meters | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 9/12/18/24/30 | |

| Lifting speed (/slow) | m/min | 8 | 8 | 8 | 8 | 7 | |

| Running speed | m/min | 20 | 20 | 20 | 20 | 20 | |

| Wire rope | Rope Diameter | mm | 7.4 | 11 | 13 | 15.5 | 15.5 |

| Wire Diameter | mm | 0.34 | 0.5 | 0.6 | 0.7 | 0.7 | |

| Structural form | 18*7+IWS | 18*7+IWS | 18*7+IWS | 18*7+IWS | 18*7+IWS | ||

| I-beam track model GB706-65 | 16-28b | 20a-32c | 20a-32c | 25a-45c | 32b-63c | ||

| Working Grade | M6 | M6 | M6 | M6 | M6 | ||

| Model | YZD 22-4 | YZD 31-4 | YZD 32-4 | YZD 41-4 | YZD 51-4 | ||

| Hoisting motor | Capacity | kW | 1.5 | 3 | 4.5 | 7.5 | 13 |

| RPM | rpm | 1380 | 1380 | 1380 | 1380 | 1380 | |

| Number of phases | 3 | 3 | 3 | 3 | 3 | ||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | |

| Current | Ampere | 4.3 | 7.6 | 11 | 18 | 30 | |

| Frequency | Weeks/Seconds | 50 | 50 | 50 | 50 | 50 | |

| Model | YZD 12-4 | YZD 12-4 | YZD 12-4 | YZD21-4 | YZD21-4 | ||

| Running motor | capacity | kW | 0.4 | 0.4 | 0.4 | 0.8 | 0.8 |

| RPM | rpm | 1380 | 1380 | 1380 | 1380 | 1380 | |

1. Industry Position

Founded in 2006, Dafang Heavy Machine covers an area of 1,580 mu and employs over 2,600 people. With an annual sales revenue of 3.566 billion RMB, the company focuses on two main business sectors: lifting machinery and steel structures. Major products include single and double girder bridge and gantry cranes, electric hoists, steel structure bridges, prefabricated buildings, and industrial plants. Dafang serves critical sectors such as military industry, aerospace, nuclear power, offshore engineering, metallurgy, and mining. Its products are exported to over 100 countries and regions, including the United States, Russia, and Southeast Asia.

Annually, Dafang manufactures 30,000 single-girder cranes, more than 12,000 double-girder and gantry cranes, and 30,000 electric hoists. Based on production scale, sales volume, and brand recognition, the company ranks among the top three in China’s crane industry.

2. Core Technologies

Dafang’s R&D team consists of over 260 members, including 104 with senior or intermediate engineering qualifications. The company invests 3.8% of its annual sales into technology development. It has obtained 12 international invention patents, 50 national invention patents, 415 utility model patents, and achieved 43 scientific and technological milestones. Dafang was the first in the industry to adopt anti-sway and automatic positioning technologies.

In 2016, Dafang became the first enterprise in Henan Province to implement smart crane applications and to introduce remote monitoring technology. The company also developed the multifunctional brewing crane, filling a domestic market gap. In 2021, Dafang was the first in the industry to be certified for unmanned intelligent cranes. In 2022, it undertook a project for a tower crane at a commercial satellite launch site.

3. Manufacturing Capability

Dafang Heavy Machine is equipped with advanced in-house designed manufacturing equipment, including 1,500-ton press grooving machines, extrusion machines, and roller machines. The company has established leading domestic workshops, including an electrical assembly line, steel pre-processing line, paint finishing line, and China’s first practical single-girder lean production line. Precision machinery includes imported German NILES CNC gear grinding machines and Japanese MAZAK machining centers.

4. Service Assurance

Dafang upholds a “comprehensive, high-quality” service standard, providing users with fast, attentive, and thorough one-stop services. With 24/7 online support, choosing Dafang means complete peace of mind. Just tell us what you need—we’ll take care of the rest.

When choosing a metallurgical electric hoist, it is recommended that the rated load capacity be at least 20%-30% higher than the actual need (for example, if you need to lift 5 tons of material, choose a 6-ton model). The lifting height is usually between 10 and 30 meters and can be customized based on actual needs.

Our metallurgical electric hoists are equipped with multiple safety features, including overload protection, mechanical and electronic limit switches, emergency braking systems, etc., ensuring safe operation in harsh working environments.

Yes, the metallurgical electric hoist is designed for high-temperature environments. It uses heat-resistant materials and explosion-proof motors, enabling stable operation in environments up to 500°C, meeting the needs of high-temperature workplaces such as metallurgy and casting.

The maintenance cost of the metallurgical electric hoist is relatively low. The equipment uses wear-resistant materials and has a simple structural design, making it easy to perform regular inspections and part replacements, reducing maintenance expenses over the long term.