The MD electric hoist is a small and lightweight lifting device that can be installed on hoist single beams, bridge cranes, gantry cranes, and jib cranes. With slight modifications, it can also be used as a winch. Therefore, it is one of the commonly used lifting devices in factories, mines, ports, warehouses, cargo yards, and stores. It is an essential piece of machinery to improve labor efficiency and working conditions.

The MD electric hoist offers two lifting speeds—normal speed and slow speed. When operating at slow speed, it meets the requirements for precision tasks such as precise loading and unloading, sand box mold closing, and machine tool maintenance.

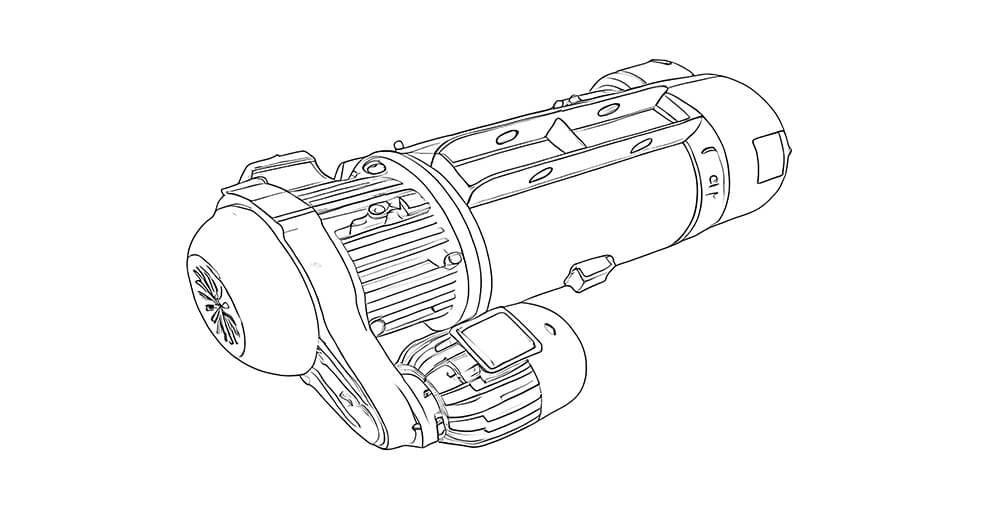

The core component of the hoist is the motor, which provides the power for the wire rope drum to rotate, thereby lifting and lowering the load. The design of the motor axis ensures a compact structure and effective transmission. Additionally, the electric hoist is equipped with a reducer that connects the motor and the drum. The reducer is primarily used to reduce the speed and increase the torque to ensure smooth and reliable lifting. Moreover, the design of the electric hoist takes into account continuous operation and efficiency, so high durability and effectiveness were considered when selecting materials and manufacturing processes. For example, key components made from high-strength alloy steel extend the product's service life. The optimized electrical control system helps improve operational precision and response speed. For applications requiring frequent use, products with wireless remote control functionality are available, enabling remote operation and increasing convenience.

MD electric hoists are widely used in factories, mines, ports, warehouses, freight yards, and stores. They are a commonly used lifting device that significantly improves labor efficiency and enhances working conditions. MD electric hoists can be installed on single beam cranes, bridge cranes, gantry cranes, and jib cranes. With slight modifications, they can also be used as winches. Their versatility makes them suitable for various lifting tasks in industrial and commercial environments.

MD electric hoists offer two lifting speeds – normal and slow. The slow speed is particularly beneficial for precision lifting tasks such as mold closing, machine tool maintenance, and delicate loading and unloading operations, ensuring greater control and accuracy.

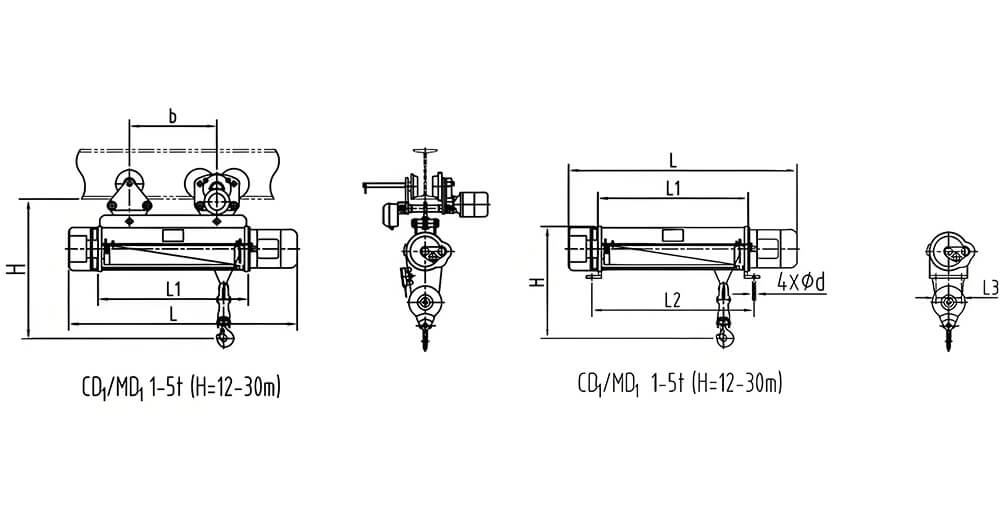

The MD hoist is designed with a compact structure, ensuring space efficiency while maintaining a robust and durable build. The motor and reducer components are engineered for longevity and reliability, providing long-term service even in heavy-duty applications.

The hoist is equipped with a high-performance electrical control system that improves operational precision and enhances responsiveness. It is also compatible with wireless remote control systems, allowing for greater operational convenience and reducing physical contact with the equipment.

The key components of the MD electric hoist, including the motor, gearbox, and hoist drum, are built from high-strength materials, ensuring excellent wear resistance and reliability. These high-quality parts contribute to the hoist's longevity and low maintenance needs.

Designed with energy-saving in mind, MD electric hoists reduce energy consumption by up to 30% compared to traditional models. The incorporation of frequency conversion technology further boosts work efficiency by more than 20%, reducing operational costs.

| Lifting capacity | 3t | 5t | 10t | 16t |

| Working Class | A3 | |||

| Wire Rope Length | 3.6-25.5 meter | |||

| Hoisting height | 3-30 meter | |||

| Hoisting speed | 8/0.8/8 m/min | 7/0.7/7m/min | 3.5/0.35/3.5m/min | |

| Travelling speed | 20-30 m/min | |||

| Working system | FC=25%(intermediate) | |||

| Power Source | AC 380V 50HZ | |||

1. Industry Position

Founded in 2006, Dafang Heavy Machine covers an area of 1,580 mu and employs over 2,600 people. With an annual sales revenue of 3.566 billion RMB, the company focuses on two main business sectors: lifting machinery and steel structures. Major products include single and double girder bridge and gantry cranes, electric hoists, steel structure bridges, prefabricated buildings, and industrial plants. Dafang serves critical sectors such as military industry, aerospace, nuclear power, offshore engineering, metallurgy, and mining. Its products are exported to over 100 countries and regions, including the United States, Russia, and Southeast Asia.

Annually, Dafang manufactures 30,000 single-girder cranes, more than 12,000 double-girder and gantry cranes, and 30,000 electric hoists. Based on production scale, sales volume, and brand recognition, the company ranks among the top three in China’s crane industry.

2. Core Technologies

Dafang’s R&D team consists of over 260 members, including 104 with senior or intermediate engineering qualifications. The company invests 3.8% of its annual sales into technology development. It has obtained 12 international invention patents, 50 national invention patents, 415 utility model patents, and achieved 43 scientific and technological milestones. Dafang was the first in the industry to adopt anti-sway and automatic positioning technologies.

In 2016, Dafang became the first enterprise in Henan Province to implement smart crane applications and to introduce remote monitoring technology. The company also developed the multifunctional brewing crane, filling a domestic market gap. In 2021, Dafang was the first in the industry to be certified for unmanned intelligent cranes. In 2022, it undertook a project for a tower crane at a commercial satellite launch site.

3. Manufacturing Capability

Dafang Heavy Machine is equipped with advanced in-house designed manufacturing equipment, including 1,500-ton press grooving machines, extrusion machines, and roller machines. The company has established leading domestic workshops, including an electrical assembly line, steel pre-processing line, paint finishing line, and China’s first practical single-girder lean production line. Precision machinery includes imported German NILES CNC gear grinding machines and Japanese MAZAK machining centers.

4. Service Assurance

Dafang upholds a “comprehensive, high-quality” service standard, providing users with fast, attentive, and thorough one-stop services. With 24/7 online support, choosing Dafang means complete peace of mind. Just tell us what you need—we’ll take care of the rest.

It is recommended to select a hoist with a rated load 20%–30% higher than your actual needs. For example, if you are lifting a 3-ton load, choose a 4-ton model to avoid overloading risks and ensure long-term reliability.

MD electric hoists are built for durability, with a design that minimizes wear and tear. When used under normal operating conditions, the hoist can provide years of reliable service. Regular maintenance will further extend its lifespan.

The MD electric hoist requires minimal maintenance. The key maintenance activities include inspecting the wire rope, lubricating the gearbox, and ensuring that the electrical components are functioning properly. The hoist is designed to be low-maintenance, with durable parts that reduce wear.

Yes, the MD electric hoist is available in a variety of configurations, including different lifting capacities, speeds, and control options. We can work with you to customize the hoist to meet your specific requirements, ensuring optimal performance for your applications.