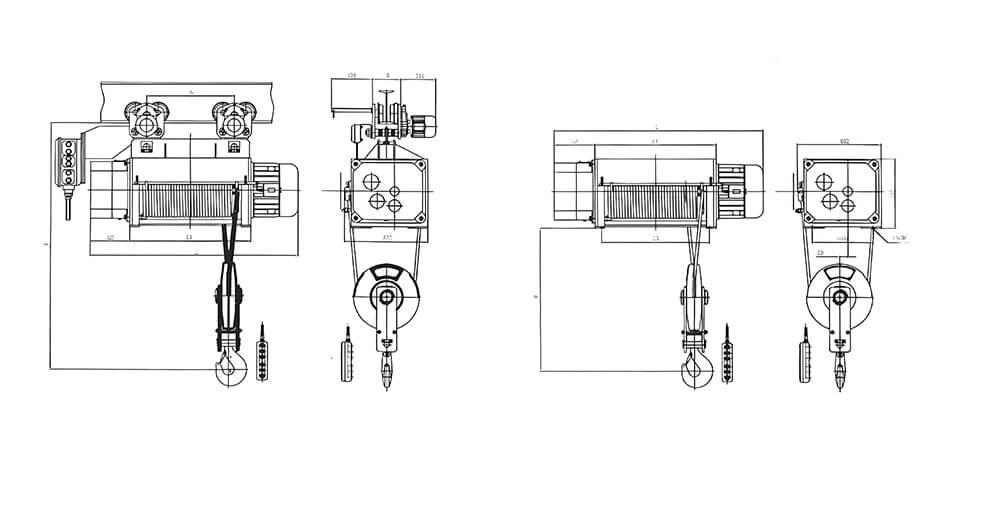

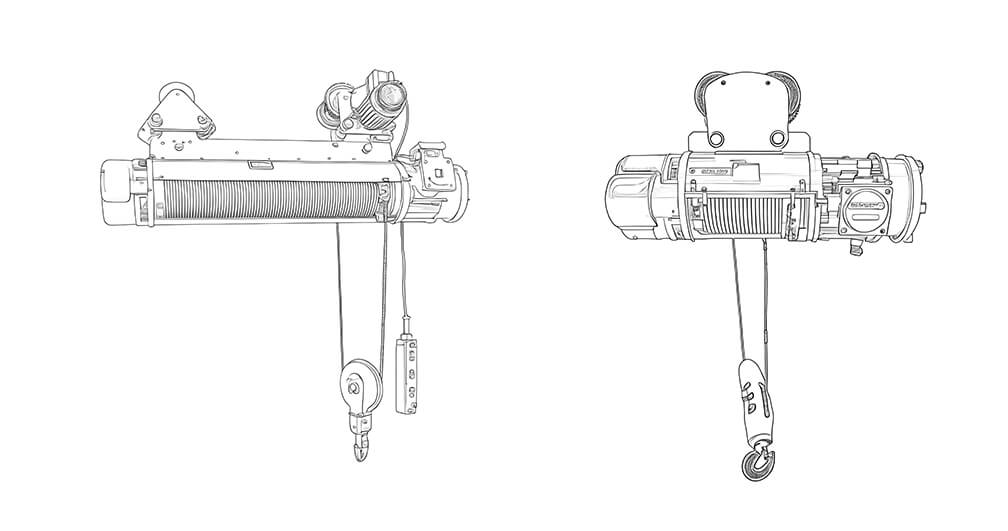

The explosion-proof wire rope electric hoist lifting mechanism adopts the classic "I" shaped series structure, where the motor and gearbox are arranged on both sides of the drum assembly. The motor transmits power to the gearbox through a drive mechanism set inside the drum device, and the gearbox output shaft spline drives the drum assembly to wind the steel rope.

The electric hoist is classified based on lifting speed into single-speed and double-speed models; based on headroom type, it is available in standard headroom and low headroom types; based on traveling performance, it comes in running and fixed types; and based on explosion-proof types, it is available in gas explosion-proof and dust explosion-proof types.

The electric hoist can be adapted for use with fixed tracks, electric single-beam cranes, electric gantry cranes, hoist gantry cranes, and hoist double-beam cranes, offering a wide range of applications.

Explosion-proof hoists can be used in combination with explosion-proof single-track trolleys to form manual lifting and transportation trolleys. Explosion-proof hoists are widely used in potentially hazardous environments with fire and explosion risks, such as petroleum, petrochemical, oil stations, oil depots, gas extraction, chemical, military, power, mining, electronics, and railways. During operation, the product's friction and impact will not generate mechanical sparks, effectively preventing fire accidents and ensuring the safety of national property and personnel. They are also essential tools for machinery manufacturing and maintenance. The rotating gears of the explosion-proof hoist are heat-treated at high temperatures, ensuring high wear resistance. The manual chain hoist has a small pulling force, is lightweight, easy to carry, and features an attractive appearance. It is compact, durable, and designed to last.

Explosion-proof electric hoists are designed for use in hazardous environments with flammable and explosive risks. They are widely used in industries such as petroleum, chemicals, coal mining, and power generation, especially in locations where there is a danger of gas or dust explosions, such as oil fields, chemical plants, pharmaceutical factories, coal mines, and smelting plants. They are typically installed on fixed tracks, overhead cranes, gantry cranes, and bridge cranes to lift heavy objects and work equipment, ensuring safe and efficient production processes.

Explosion-proof electric hoists comply with international explosion-proof standards (such as ATEX and IECEx certifications), ensuring safe operation in explosive gas and dust environments and preventing accidents caused by electrical equipment failure.

Equipped with high-efficiency motors and precision reducers, providing smooth lifting and operation. It maintains high performance and durability even in harsh environments.

Explosion-proof electric hoists are available in various models based on different needs, including single speed, double speed, and low headroom types. They are compatible with various lifting equipment and are widely used in multiple industries.

Easy to operate, equipped with remote controls or button controls, allowing operators to perform remote control conveniently. Additionally, the design simplifies maintenance, ensuring long-term stable operation.

1. Industry Position

Founded in 2006, Dafang Heavy Machine covers an area of 1,580 mu and employs over 2,600 people. With an annual sales revenue of 3.566 billion RMB, the company focuses on two main business sectors: lifting machinery and steel structures. Major products include single and double girder bridge and gantry cranes, electric hoists, steel structure bridges, prefabricated buildings, and industrial plants. Dafang serves critical sectors such as military industry, aerospace, nuclear power, offshore engineering, metallurgy, and mining. Its products are exported to over 100 countries and regions, including the United States, Russia, and Southeast Asia.

Annually, Dafang manufactures 30,000 single-girder cranes, more than 12,000 double-girder and gantry cranes, and 30,000 electric hoists. Based on production scale, sales volume, and brand recognition, the company ranks among the top three in China’s crane industry.

2. Core Technologies

Dafang’s R&D team consists of over 260 members, including 104 with senior or intermediate engineering qualifications. The company invests 3.8% of its annual sales into technology development. It has obtained 12 international invention patents, 50 national invention patents, 415 utility model patents, and achieved 43 scientific and technological milestones. Dafang was the first in the industry to adopt anti-sway and automatic positioning technologies.

In 2016, Dafang became the first enterprise in Henan Province to implement smart crane applications and to introduce remote monitoring technology. The company also developed the multifunctional brewing crane, filling a domestic market gap. In 2021, Dafang was the first in the industry to be certified for unmanned intelligent cranes. In 2022, it undertook a project for a tower crane at a commercial satellite launch site.

3. Manufacturing Capability

Dafang Heavy Machine is equipped with advanced in-house designed manufacturing equipment, including 1,500-ton press grooving machines, extrusion machines, and roller machines. The company has established leading domestic workshops, including an electrical assembly line, steel pre-processing line, paint finishing line, and China’s first practical single-girder lean production line. Precision machinery includes imported German NILES CNC gear grinding machines and Japanese MAZAK machining centers.

4. Service Assurance

Dafang upholds a “comprehensive, high-quality” service standard, providing users with fast, attentive, and thorough one-stop services. With 24/7 online support, choosing Dafang means complete peace of mind. Just tell us what you need—we’ll take care of the rest.

Explosion-proof electric hoists are suitable for areas with explosive gas or dust hazards, such as industries like petroleum, chemicals, and power generation. The products comply with explosion-proof certifications like ATEX and IECEx, ensuring safe operation in these hazardous environments.

When selecting the appropriate model, you need to consider factors such as lifting height, load capacity, clearance requirements in the working environment, and whether a low headroom design is necessary. We offer various models to meet different application needs.

Explosion-proof electric hoists are equipped with multiple safety features, such as overload protection, limit switches, and automatic shutdown systems, to ensure that no malfunction occurs during operation. All explosion-proof electrical components comply with explosion-proof standards to ensure safe operation.

The maintenance of explosion-proof electric hoists is similar to that of conventional electric hoists, mainly involving regular checks of the electrical systems and mechanical components for wear. Additionally, we offer regular maintenance suggestions and spare parts supply to ensure long-term stable operation.