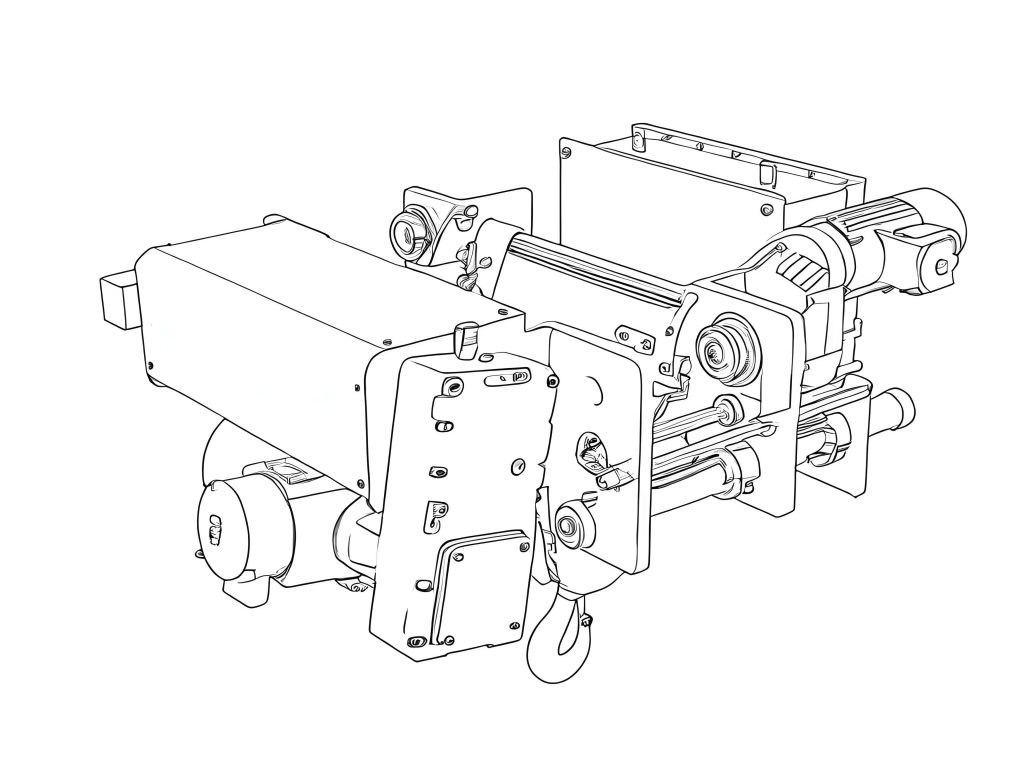

The European-style explosion-proof wire rope electric hoist is a new generation of lifting equipment developed according to European FEM and IEC standards. It combines advanced explosion-proof technology with the compact, efficient, and reliable design of European-style hoists. Designed specifically for use in hazardous environments containing flammable gases or combustible dust, this hoist ensures maximum safety while delivering high lifting performance.

Electric hoists are ideal for assembly lines and material handling in industries such as automotive and machinery manufacturing. They allow for precise lifting of heavy components, improving assembly efficiency while reducing manual handling risks.

They support automated production lines and, when paired with overhead cranes and tracks, enable cross-zone material transfer.

For heavy equipment maintenance and installation, electric hoists allow quick lifting of parts during electromechanical repairs, significantly reducing downtime.

On construction sites, electric hoists are used for lifting materials such as rebar and concrete components, addressing the inefficiency and danger of traditional manual handling.

They are widely applied in high-rise building construction for vertical transportation of materials and equipment to upper floors.

In bridge and large-structure projects, hoists assist in the installation and positioning of steel components, adapting to complex construction environments.

Electric hoists enable quick loading and unloading of heavy goods in warehouses, optimizing space utilization and reducing labor costs.

When integrated with container-handling equipment, they boost operational efficiency in ports and logistics parks.

They are also used for loading and unloading cargo trucks and lorries, especially for bulk materials such as ores and industrial raw materials.

In mining and agricultural work, hoists assist in transporting ores and equipment, reducing worker fatigue.

On farms, they handle heavy items such as agricultural machinery and feed, increasing agricultural productivity.

Small factories use them to handle electronic components or handicrafts, reducing the risk of manual handling damage.

In explosion-proof and high-temperature environments, such as in the chemical and oil & gas industries, intrinsically safe electric hoists certified by ATEX and similar standards ensure reliable operation.

High-temperature-resistant hoist models are suitable for use in metallurgical and foundry workshops.

In precision control scenarios, variable-frequency hoists allow micro-speed lifting, which is essential for the installation of delicate equipment.

| Model Specification | HY1T | HY2T | HY3T | HY5T | HY10T | ||

| Lifting height | meters | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 6/9/12/18/24/30 | 9/12/18/24/30 | |

| Lifting speed (/slow) | m/min | 8 | 8 | 8 | 8 | 7 | |

| Running speed | m/min | 20 | 20 | 20 | 20 | 20 | |

| Wire rope | Rope Diameter | mm | 7.4 | 11 | 13 | 15.5 | 15.5 |

| Wire Diameter | mm | 0.34 | 0.5 | 0.6 | 0.7 | 0.7 | |

| Structural form | 18*7+IWS | 18*7+IWS | 18*7+IWS | 18*7+IWS | 18*7+IWS | ||

| I-beam track model GB706-65 | 16-28b | 20a-32c | 20a-32c | 25a-45c | 32b-63c | ||

| Working Grade | M6 | M6 | M6 | M6 | M6 | ||

| Model | YZD 22-4 | YZD 31-4 | YZD 32-4 | YZD 41-4 | YZD 51-4 | ||

| Hoisting motor | Capacity | kW | 1.5 | 3 | 4.5 | 7.5 | 13 |

| RPM | rpm | 1380 | 1380 | 1380 | 1380 | 1380 | |

| Number of phases | 3 | 3 | 3 | 3 | 3 | ||

| Voltage | Volt | 380 | 380 | 380 | 380 | 380 | |

| Current | Ampere | 4.3 | 7.6 | 11 | 18 | 30 | |

| Frequency | Weeks/Seconds | 50 | 50 | 50 | 50 | 50 | |

| Model | YZD 12-4 | YZD 12-4 | YZD 12-4 | YZD21-4 | YZD21-4 | ||

| Running motor | capacity | kW | 0.4 | 0.4 | 0.4 | 0.8 | 0.8 |

| RPM | rpm | 1380 | 1380 | 1380 | 1380 | 1380 | |

The entire hoist is designed with explosion-proof components including motors, control cabinets, and electrical devices, ensuring safe operation in Zone 1 and Zone 2 hazardous areas.

The European modular design allows for smaller dimensions, reduced wheel pressure, and increased lifting height, enhancing space utilization.

The hoist features a hardened gear reducer, high-performance wire rope, and automatic brake adjustment, offering smooth, reliable, and low-noise operation.

Equipped with dual-speed or frequency-conversion drive, it ensures precise lifting and positioning while reducing energy consumption.

Designed for long service life, with components like maintenance-free steel wire rope and lubrication-free bearings, significantly reducing downtime and service costs.

Load capacities from 1 ton to 50 tons (or more) are available, with customizable lifting height, voltage, explosion-proof grade, and control mode based on customer needs.

1. Industry Position

Founded in 2006, Dafang Heavy Machine covers an area of 1,580 mu and employs over 2,600 people. With an annual sales revenue of 3.566 billion RMB, the company focuses on two main business sectors: lifting machinery and steel structures. Major products include single and double girder bridge and gantry cranes, electric hoists, steel structure bridges, prefabricated buildings, and industrial plants. Dafang serves critical sectors such as military industry, aerospace, nuclear power, offshore engineering, metallurgy, and mining. Its products are exported to over 100 countries and regions, including the United States, Russia, and Southeast Asia.

Annually, Dafang manufactures 30,000 single-girder cranes, more than 12,000 double-girder and gantry cranes, and 30,000 electric hoists. Based on production scale, sales volume, and brand recognition, the company ranks among the top three in China’s crane industry.

2. Core Technologies

Dafang’s R&D team consists of over 260 members, including 104 with senior or intermediate engineering qualifications. The company invests 3.8% of its annual sales into technology development. It has obtained 12 international invention patents, 50 national invention patents, 415 utility model patents, and achieved 43 scientific and technological milestones. Dafang was the first in the industry to adopt anti-sway and automatic positioning technologies.

In 2016, Dafang became the first enterprise in Henan Province to implement smart crane applications and to introduce remote monitoring technology. The company also developed the multifunctional brewing crane, filling a domestic market gap. In 2021, Dafang was the first in the industry to be certified for unmanned intelligent cranes. In 2022, it undertook a project for a tower crane at a commercial satellite launch site.

3. Manufacturing Capability

Dafang Heavy Machine is equipped with advanced in-house designed manufacturing equipment, including 1,500-ton press grooving machines, extrusion machines, and roller machines. The company has established leading domestic workshops, including an electrical assembly line, steel pre-processing line, paint finishing line, and China’s first practical single-girder lean production line. Precision machinery includes imported German NILES CNC gear grinding machines and Japanese MAZAK machining centers.

4. Service Assurance

Dafang upholds a “comprehensive, high-quality” service standard, providing users with fast, attentive, and thorough one-stop services. With 24/7 online support, choosing Dafang means complete peace of mind. Just tell us what you need—we’ll take care of the rest.

The rated load should be 20%-30% higher than the actual lifting demand (e.g., for lifting 3 tons of goods, choose a 4-ton model) to avoid overload risks.

For low-clearance workshops, compact designs with hook approach ≤400mm are preferred. Standard lifting heights range from 6 to 30 meters and can be customized as needed.

Triple protection is mandatory: automatic power cut-off for overload, dual mechanical and electronic limit switches, and an emergency braking system.

Wire ropes must be coated with rust-proofing, and the broken wire rate must be regularly inspected (replace immediately if it exceeds 10%).

Explosion-proof models must be certified with ATEX/IECEx standards. The explosion-proof grade should specify both the temperature class (e.g., T4) and gas group (IIB/IIC).

Transmission components must use bronze or nickel-alloy materials to prevent mechanical sparks.

Choosing IE3 energy-efficient motors can reduce power consumption by 30%. Frequency converters are recommended to be replaced every 5 years.

Our company provides full spare parts support, ensuring timely delivery of critical components such as gearboxes and brake discs.

For -30°C environments, low-temperature lubricants and motor preheating modules are required. In high-temperature environments (+60°C), enhanced insulation layers are necessary.

Outdoor models must be equipped with wind anchor devices, with wind resistance level reaching grade 10 or above. Customizations are available according to specific scenarios.