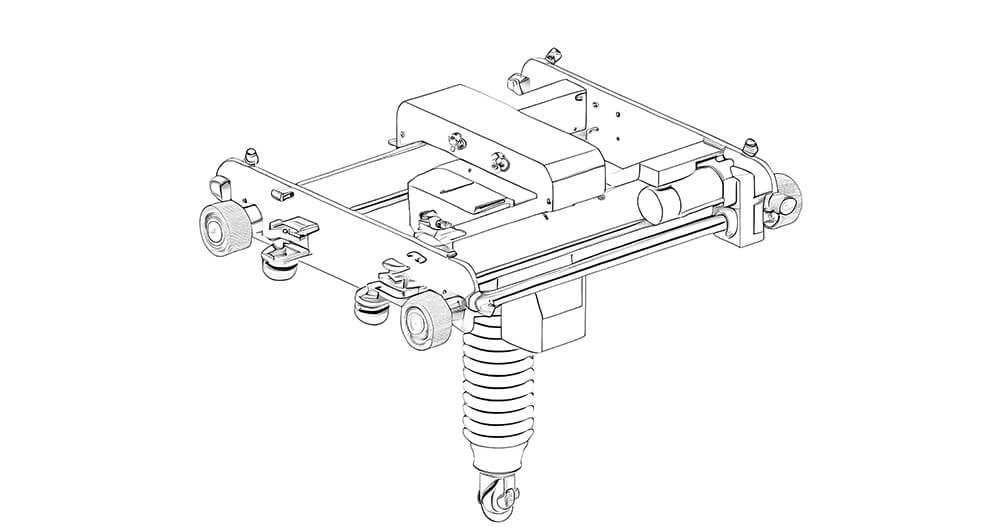

The dust-free clean electric hoist is specifically designed for lifting equipment in environments with strict cleanliness requirements, such as clean rooms, food and pharmaceutical industries, and precision electronics manufacturing. The core design focuses on dust and contamination prevention to ensure stable and reliable lifting performance.

It features a fully enclosed dustproof structure to ensure no particle contamination during the lifting process. The entire hoist is made of stainless steel or corrosion-resistant aluminum alloy materials, with a smooth surface that facilitates cleaning and disinfection, while also being resistant to corrosion from common chemical solvents used in workshops.

The hook is treated with mirror polishing to reduce dust accumulation. The steel wire rope is coated with stainless steel or polyester fiber coating to maintain cleanliness. Users can also choose high-strength polyester fiber slings as an alternative to metal cables, further reducing contamination risks. Key components such as limit switches are also sealed to prevent particles from affecting accuracy.

The control box is fully sealed, with buttons made of silicone or a touchscreen to avoid particle generation from mechanical wear. A wireless remote control is used to reduce surface contact contamination. The operating noise of the entire hoist is kept below 60 decibels, meeting the strict noise environment requirements of clean rooms.

The dust-free electric hoist is designed for high cleanliness environments, widely used in clean rooms, food processing, pharmaceutical manufacturing, and precision electronics industries. The core design focuses on dust and contamination prevention, ensuring efficient lifting operations while maintaining the cleanliness of the environment. This hoist is especially suitable for workplaces requiring extremely high cleanliness standards, ensuring that lifting operations do not cause contamination.

The hoist is equipped with a seamless 304 stainless steel shell, mirror-polished to completely eliminate dust generation. The motor and transmission system use multi-layer seals to ensure zero contamination during operation, meeting ISO Class 4 and higher cleanliness standards.

Innovative magnetic sealing technology eliminates the need for traditional gear lubricants. The use of self-lubricating bearings and ceramic-coated components thoroughly prevents oil leakage, making it suitable for high-demand environments such as food and pharmaceuticals.

It is equipped with a brushless servo motor, generating noise levels below 55 decibels. The intelligent variable frequency control reduces energy consumption by 40% compared to conventional models, offering energy savings and environmental friendliness.

The hoist supports both touchscreen and wireless remote control modes. It includes built-in operation data recording capabilities for real-time equipment monitoring, and enables remote fault diagnosis.

The modular quick-disassembly structure allows for deep cleaning within 30 minutes. All interfaces are dustproof, and maintenance requires no special tools, significantly reducing downtime.

| Product name | Clean Type Electric Hoist for Workshop | |||

| Lifting capacity | 3t | 5t | 10t | 20t |

| Working Class | A3-A5 | |||

| Working tempreture | -20°C~40°C | |||

| Hoisting height | 6m-30m | |||

| Hoisting speed | 8/0.8/8 m/min | 7/0.7/7m/min | 3.5/0.35/3.5m/min | |

| Crane Travelling speed | 20m/min | |||

| Working system | 25% | |||

| Power Source | AC 380V 50HZ | |||

1. Industry Position

Founded in 2006, Dafang Heavy Machine covers an area of 1,580 mu and employs over 2,600 people. With an annual sales revenue of 3.566 billion RMB, the company focuses on two main business sectors: lifting machinery and steel structures. Major products include single and double girder bridge and gantry cranes, electric hoists, steel structure bridges, prefabricated buildings, and industrial plants. Dafang serves critical sectors such as military industry, aerospace, nuclear power, offshore engineering, metallurgy, and mining. Its products are exported to over 100 countries and regions, including the United States, Russia, and Southeast Asia.

Annually, Dafang manufactures 30,000 single-girder cranes, more than 12,000 double-girder and gantry cranes, and 30,000 electric hoists. Based on production scale, sales volume, and brand recognition, the company ranks among the top three in China’s crane industry.

2. Core Technologies

Dafang’s R&D team consists of over 260 members, including 104 with senior or intermediate engineering qualifications. The company invests 3.8% of its annual sales into technology development. It has obtained 12 international invention patents, 50 national invention patents, 415 utility model patents, and achieved 43 scientific and technological milestones. Dafang was the first in the industry to adopt anti-sway and automatic positioning technologies.

In 2016, Dafang became the first enterprise in Henan Province to implement smart crane applications and to introduce remote monitoring technology. The company also developed the multifunctional brewing crane, filling a domestic market gap. In 2021, Dafang was the first in the industry to be certified for unmanned intelligent cranes. In 2022, it undertook a project for a tower crane at a commercial satellite launch site.

3. Manufacturing Capability

Dafang Heavy Machine is equipped with advanced in-house designed manufacturing equipment, including 1,500-ton press grooving machines, extrusion machines, and roller machines. The company has established leading domestic workshops, including an electrical assembly line, steel pre-processing line, paint finishing line, and China’s first practical single-girder lean production line. Precision machinery includes imported German NILES CNC gear grinding machines and Japanese MAZAK machining centers.

4. Service Assurance

Dafang upholds a “comprehensive, high-quality” service standard, providing users with fast, attentive, and thorough one-stop services. With 24/7 online support, choosing Dafang means complete peace of mind. Just tell us what you need—we’ll take care of the rest.

This hoist features a seamless 304 stainless steel shell with a mirror polish to completely eliminate dust generation, meeting ISO Class 4 and higher cleanliness standards. All components are treated with dustproof designs to ensure no particle accumulation during prolonged use.

The hoist uses multi-layer sealing technology with a tightly sealed motor and transmission system to ensure that no oil or particulate contamination occurs during operation. Additionally, the innovative magnetic sealing technology eliminates the need for traditional lubricating oils, fully meeting the high requirements of the food and pharmaceutical industries.

The dust-free electric hoist is equipped with a brushless servo motor, with noise levels below 55 decibels. It also uses intelligent variable frequency control, reducing energy consumption by 40% compared to traditional models, thus saving energy and lowering operational costs.

The hoist features a modular quick-disassembly structure, allowing for deep cleaning within 30 minutes. All interfaces are designed to be dustproof, and maintenance requires no special tools, simplifying daily upkeep and minimizing downtime.