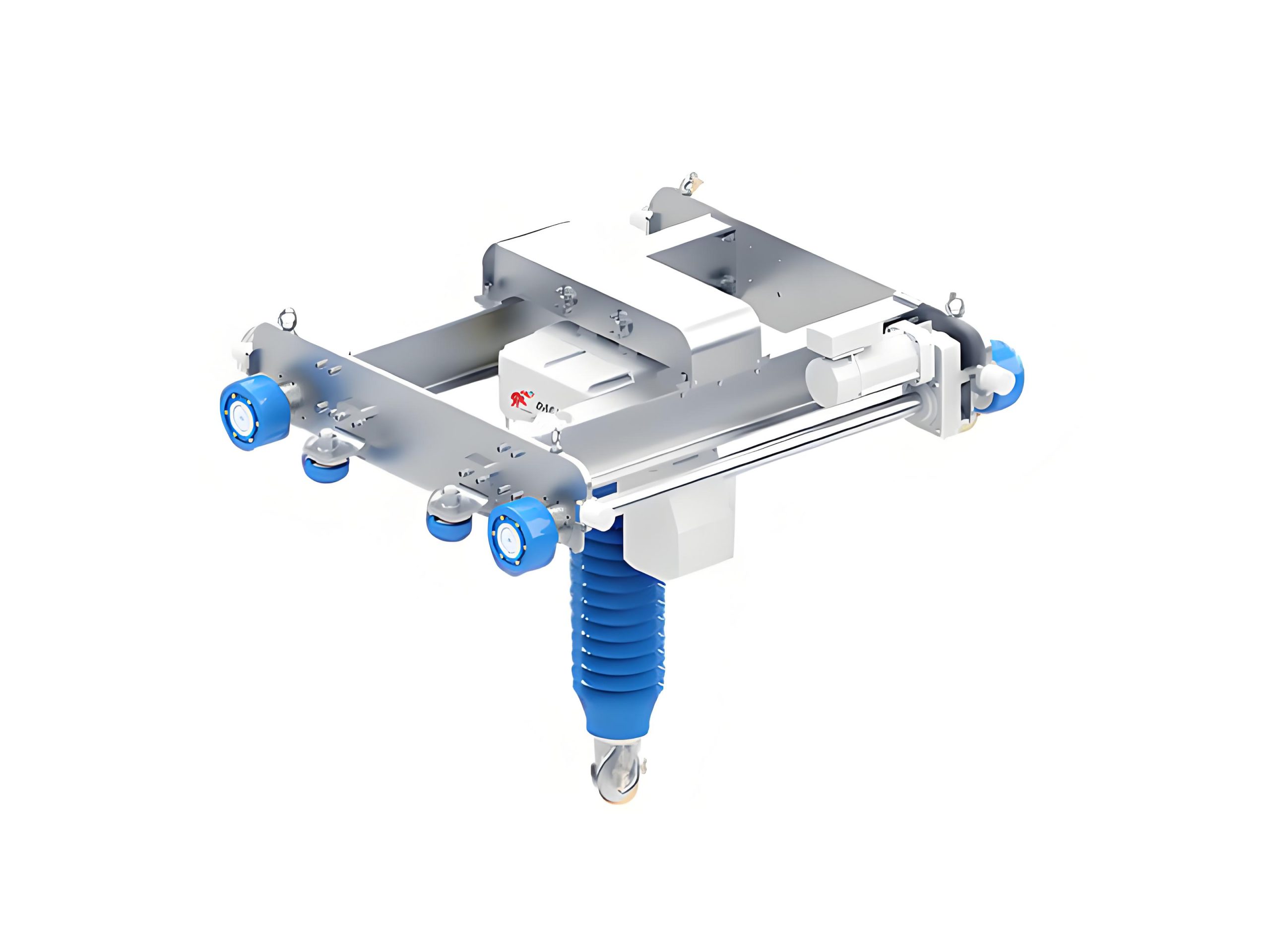

A 120-ton capacity gantry crane independently designed and manufactured by our company has been successfully commissioned at a factory site and officially put into experimental testing operation. The crane is dedicated to supporting heavy-duty experimental lifting tasks and technical verification processes, playing a critical role in the factory’s scientific research, product development, and engineering validation activities.

This gantry crane is specifically engineered to meet the demanding requirements of experimental testing environments. With its large lifting capacity, high structural rigidity, and excellent operational stability, the equipment is capable of handling oversized and heavy test components under various working conditions. The crane’s design fully considers the need for precision, safety, and repeatability, which are essential factors in laboratory-scale and industrial experimental testing.

During actual operation, the 120-ton gantry crane is used to perform repeated lifting, positioning, load simulation, and stress-testing of large components. These processes are essential for verifying product performance, evaluating structural strength, and optimizing manufacturing processes. The crane’s smooth traveling mechanism and precise hoisting control allow operators to accurately position test objects, ensuring that experimental data is reliable and repeatable while minimizing the risk of operational errors.

In addition, the crane is equipped with a reliable control system and comprehensive safety protection devices, ensuring safe operation throughout long-duration and high-frequency testing cycles. Its stable performance significantly reduces manual intervention, lowers operational risks, and improves overall testing efficiency. This makes it an ideal solution for factories and research facilities engaged in high-load experiments, prototype validation, and advanced equipment testing.

As an important part of the factory’s research and testing infrastructure, this 120-ton gantry crane not only enhances the efficiency and accuracy of experimental operations but also provides strong support for technological innovation. By enabling safer and more efficient testing of heavy components, the crane helps shorten research cycles, accelerate product development, and improve the overall competitiveness of new technologies and equipment.

Looking ahead, this gantry crane will continue to serve a wide range of high-end research and testing projects within the factory. Its stable operation and reliable performance will contribute to continuous technological breakthroughs, supporting the factory’s long-term development goals and reinforcing its capabilities in advanced engineering research and industrial innovation.